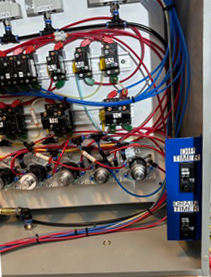

New Air Logic Conveyer

AIR LOGIC CONVEYER

There are 10 sequence logic controls used for highly explosive dipping processes when making rubber products. it controls the conveyer, comb clamps, part clamps, dipping, dip timer, retract head, dwelling, unclamps the combs, and unclamps the parts, releases the brakes then sends the conveyer to the next position, one of 85, done continuously all pneumatic logic.

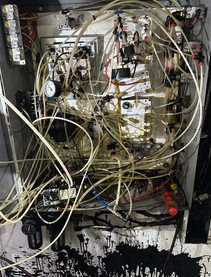

I created a new air logic controller because the old one was outdated and maintenance was unable to repair the system. The components were outdated, the pneumatic diagrams were not updated and system was faulty which made it almost impossible to diagnose. When a system is faulty, the machine stops, becomes out of sequence dropping parts, sequence off, damage part fixtures and to the conveyer components. The new system reduced down time and loss production, new prints were established and easy to diagnose the problem.

Old Air Logic Conveyer