Products Overview

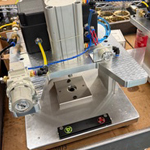

3-position Set Up Logic Controller

A based the thickness of cardboard that moves through the conveyer system the operator has adjust the glue head for each of the three levels thicknesses which use to be done manually...

More

Air Logic Conveyer

There are 10 sequence logic controls used for highly explosive dipping processes when making rubber products. it controls the conveyer, comb clamps, part clamps, dipping, dip timer, retract head, dwelling, unclamps the combs, and unclamps the parts, releases the brakes then sends the conveyer to the next position, one of 85, done continuously all pneumatic logic.

More

Pneumatic Logic Automatic Stamping Machine

Pneumatically operating machine that automatically replenishes the ink pad and self-centers the part and automatically stamps it. The system is completely pneumatic air logic controlled.

Details

Pneumatic Logic Sequencing Circuit

Prior to Creative Systems Optimized, LLC intervening, an operator would have to manually turn the valves off. often they would forget to turn the m back on in the correct sequence, resulting in large tanks being contaminated. Thousands of gallon tanks would have to be discarded causing a loss of production and added expense.Details

Pneumatic Logic Mini Press

Prior to my design, an operator would have preformed that task with a hammer and punch, resulting in scrap waste. The design is a precision press that was designed for the purpose of pressing details together in the process of assembly within 1000th of an inch.Details

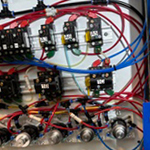

Custom Ph Monitoring System

The system monitoring controls the critical PH level for a 4-station industrial printer for water base ink. It monitors 4 ink stations and does automatic dosing if the PH level is low. It includes manual dosing manual dosing for both water and PH so that production is interrupted when performing sensor calibration procedures. A company manually checks the PH level on all 4 stations by stopping the system throughout the process and adding PH as needed. That process causes rejects, if the value is not right. The color and curing time is off which causes loss of production.Read More