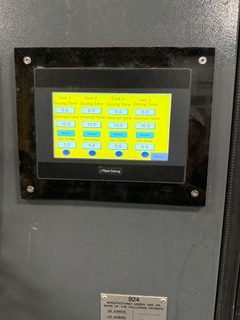

CUSTOM PH MONITORING SYSTEM

The system monitoring controls the critical PH level for a 4-station industrial printer for water base ink. It monitors 4 ink stations and does automatic dosing if the PH level is low. It includes manual dosing manual dosing for both water and PH so that production is interrupted when performing sensor calibration procedures. A company manually checks the PH level on all 4 stations by stopping the system throughout the process and adding PH as needed. That process causes rejects, if the value is not right. The color and curing time is off which causes loss of production.

The CSO system does the whole process automatically. It monitors the PH level of the ink at all times and automatically adds the calibrated dose of PH when needed. When the PH is too low it will add the calibrated amount to bring it back to the baseline. It reduces down time and increases production. It’s a customized system based on the needs of the customer.

If you have a problem with a machine with no standardization, we will put measures in place to help standardize the process.